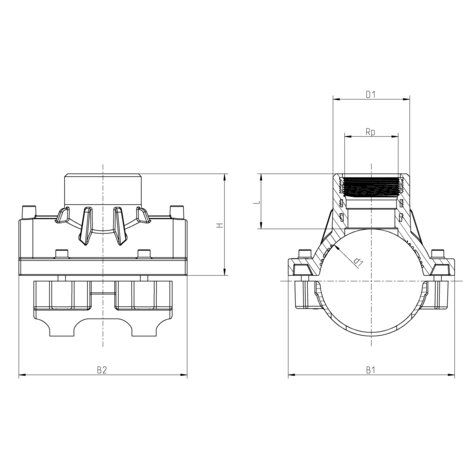

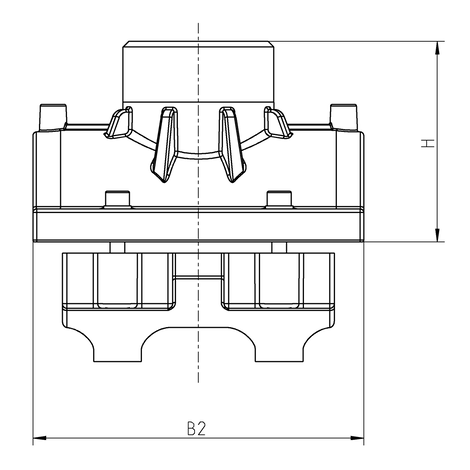

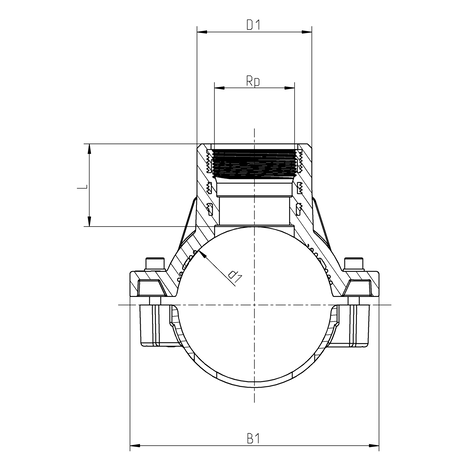

Saddle with female thread for transition HD-PE/metal

Saddle with female thread for transition HDPE/metal VA

- Gas, water

- Working pressure: MOP (gas) 10 bar, PFA (water) 16 bar

- Material: PE 100-RC and brass (female thread)

- Thread according to EN 12168-Material CW617N

- Thread according to ISO 228-1 for connections that do not seal in the thread. Cylindrical shape

- Saddle with clamp

- Safety technology

- Metals in contact with water according to UBA recommendation

PE 100 RC SDR 11

Maximum permissible working pressure 16 bar (water) / 10 bar (gas)

| Reference | Diameter | Rp | B1 | D1 | H | Weight [kg] | BX | Pallet quantity |

|---|---|---|---|---|---|---|---|---|

| 614048 | 63 | 1 1/4" | 108 | 60 | 81 | 0,440 | 20 | 360 |

| 614047 | 75 | 1 1/4" | 110 | 60 | 117 | 0,540 | 20 | 360 |

| 614049 | 90 | 2" | 156 | 82 | 103 | 0,930 | 26 | 208 |

| 614050 | 110 | 2" | 178 | 82 | 109 | 1,010 | 20 | 160 |

| 614051 | 125 | 2" | 190 | 82 | 116 | 1,190 | 20 | 160 |

| 614052 | 160 | 2" | 230 | 82 | 129 | 1,360 | 10 | 80 |

| 614053 | 180 | 2" | 235 | 82 | 125 | 1,360 | 10 | 80 |

| 614054 | 200 | 2" | 252 | 82 | 122 | 1,350 | 10 | 80 |

| 614055 | 225 | 2" | 258 | 82 | 120 | 1,370 | 10 | 80 |

Areas of Application

FRIALEN-Saddles VA and VA TL are used for transition from HDPE to metal.

Assembly Instructions

VA

After scraping and cleaning of the pipe which is being fused and cleaning of the internal surface of the FRIALEN-Saddle is screwed with the bottom section tightly to the HDPE pipe (see Assembly Instructions for “Assembly instructions FRIALEN safety fittings for sustainable pipes for gas, water networks and industrial systems made of PE”).

VA TL

The preparation of the surfaces to be fused is the same as for VA. The saddle is clamped onto the pipe with the FRIATOP clamping device (see Technical Equipment FRIATOOLS - other tools and installation aids). Please read the Assembly and Operating Instructions for FRIATOP clamping unit (Top-Loading). Fusion takes place by FRIAMAT fusing.

Good reasons for using the FRIALEN Valve Tapping Saddles:

- Compact construction

- HDPE saddles with Open Wire Technology for optimum heat transfer

- For transition from HDPE to metal

- Tapping area free of heating wires

- Type VA TL can be applied universally to large HDPE pipe diameters d 250 - 560. This means an additional economy due to less material needed and less stock both with suppliers and trade

- Additional barcode for tracing back the fitting (Traceability-Coding)