FROC/HASTELLOY - Wafer check valve with Hastelloy spring DN 32:400

Wafer check valve PVC-C with spring, version ISO-DIN.

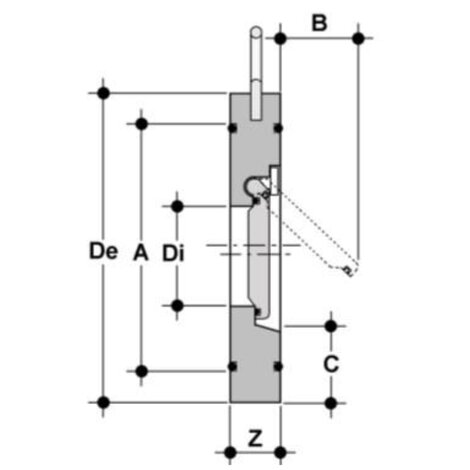

The FR wafer check valve is designed to be installed directly between stubs and flanges in accordance with ISO/ DIN, ANSI standards. Available also with springs for low backpressure applications.

Main features:

Construction: Wafer check valve

Size range: DN 32 ÷ 400

Nominal pressure: PN 10 (DN32-125), PN 6 (DN150-200), PN 5 (DN250-400) - in water at 20°C

Temperature range: 0 °C ÷ 80°C

Coupling standards: Flanging system: EN 1092-1, EN ISO 1452,EN ISO 15493,ANSI B16.5 cl.150, JIS B2220

Reference standards: Construction criteria: EN ISO 16137 EN ISO 1452, EN ISO 15493

Valve material: PVC-C

Seal material: EPDM, FKM

Spring material: SS 316, Hastelloy C4

EPDM

| Reference | Z | d | DN | g |

|---|---|---|---|---|

| FROC040EMLH | 15 | 40 | 32 | 130 |

| FROC050EMLH | 16 | 50 | 40 | 173 |

| FROC063EMLH | 18 | 63 | 50 | 290 |

| FROC075EMLX | 20 | 75 | 65 | 368 |

| FROC090EMLX | 20 | 90 | 80 | 441 |

| FROC110EMLH | 23 | 110 | 100 | 616 |

| FROC140EMLH | 23 | 140 | 125 | 834 |

| FROC160EMLH | 26 | 160 | 150 | 1233 |

| FROC225EMLH | 34 | 225 | 200 | 2333 |

| FROC280EMLH | 40 | 280 | 250 | 3919 |

| FROC315EMLH | 45 | 315 | 300 | 5874 |

| FROC355EMLH | 49 | 350 | 350 | 8538 |

| FROC400EMLH | 65 | 400 | 400 | 14103 |

FKM

| Reference | Z | d | DN | g |

|---|---|---|---|---|

| FROC040FMLH | 15 | 40 | 32 | 130 |

| FROC050FMLH | 16 | 50 | 40 | 173 |

| FROC063FMLH | 18 | 63 | 50 | 290 |

| FROC075FMLH | 20 | 75 | 65 | 368 |

| FROC090FMLH | 20 | 90 | 80 | 441 |

| FROC110FMLH | 23 | 110 | 100 | 616 |

| FROC140FMLH | 23 | 140 | 125 | 834 |

| FROC160FMLH | 26 | 160 | 150 | 1233 |

| FROC225FMLH | 34 | 225 | 200 | 2333 |

| FROC280FMLH | 40 | 280 | 250 | 3919 |

| FROC315FMLH | 45 | 315 | 300 | 5874 |

| FROC355FMLH | 49 | 350 | 350 | 8538 |

| FROC400FMLH | 65 | 400 | 400 | 14103 |

- Metal support for easy and precise centring of the valve during installation

- Can be installed in either a vertical or horizontal position

- Models with springs in INOX 316 stainless steel or Hastelloy for the conveyance of aggressive fluids.

- Sealing system with O-Rings for secure fastening and installation without flat

get_app

get_app

get_app

get_app